Blog

- How to reduce the starch damage rate of wheat flour mill?

- How does the stone flour mill influence the quality of final wheat flour?

- How to save the cost of wheat flour processing machine?

- Factors Affecting the Output of Corn Processing Machines

- How to process paddy into rice with a rice milling plant?

Hot Sale Product

Contact Us

- Mobile/WhatsApp:

008613526615783

- Phone:

008613526615783

- Email:

sales@doingoilmachine.com

Common problems in the use of corn milling machine

In the use of corn milling machine, there will be some common problems before, during and after the production of the machine. All the small factors will influence the production efficiency of your corn milling machine. Here we summarize three common problems in the use of corn milling machine, aiming to give you instructions.

1.How to use corn milling machine to improve the quality of corn flour and grits?

Some people will reflect their corn milling machine produce low quality corn flour and grits, thus they can't get much profits. According to our processing experience, there are many reasons for the poor quality of corn flour and grits, including the quality of raw corn, processing technology and the operating level of the workers. In this regard, we have summarized the following three suggestions for improving the quality of corn flour and grits:

(1)When using corn milling machine to process flour or grits, try to use high-quality raw corn suitable for processing. Corn is divided into hard grain shape and horse tooth shape according to the grain shape. Durum-shaped corn has better technological properties, and the quality of grits and flour is better.

(2)Adopt reasonable processing technology. Henan Jinrui Food Company's complete set of corn milling machine adopts dry processing technology, with high flour extraction rate, which can meet different processing needs. You can adjust parameters of every corn milling machine so that to produce high quality corn flour and girts.

(3)Train workers to standardize the operation of corn milling machine to ensure a high level of operation. Because the improper operation of the machine will lower the corn flour extraction rate and quality.

Corn milling machine to improve the quality of corn flour and grits

Corn milling machine to improve the quality of corn flour and grits

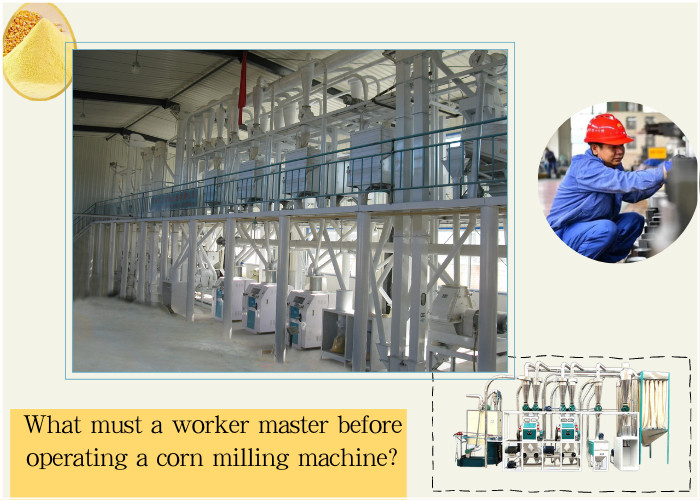

2. What must a worker master before operating a corn milling machine?

Since the complete set corn milling machine is large, workers need to master some safety knowledge before operating the machine before it can be put into production. This is not only related to the production safety of the workshop, but also affects the continuous productivity of the entire workshop.

(1)The joints of the transmission belt of the corn milling machine should be firm; it is strictly forbidden to remove or hang the belt or touch any object to the transmission part when the machine is running.

(2)The transmission ratio between the supporting power and the complete set of corn milling machine must meet the requirements, so as to avoid personal injury accidents caused by damage to parts or loose fasteners due to excessively high speed and violent vibration of the threshing machine.

(3)During the operation process, the working status of the machine can be identified through the sound. If there is a failure during the operation, it should be shut down and then repaired and adjusted.

(4)Since the working environment of corn milling machine is very harsh, it is necessary to provide safety operation education to the personnel participating in the operation in advance, so that they can understand the operating procedures and safety common sense, such as tight sleeves, wearing masks and protective glasses, etc.

(5)Before use, it is necessary to carefully check whether the rotating parts of the corn milling machine are flexible and free from collisions, whether the adjustment mechanism is normal, and whether the safety facilities are complete and effective; to ensure that there are no sundries in the machine, all lubricating parts must be lubricated.

Basic training for a worker to operate corn milling machine

Basic training for a worker to operate corn milling machine

3.What are the steps to maintain corn milling machine?

(1)Neat. Tools, workpieces, and accessories are placed neatly; safety protection devices are complete; lines and pipelines are complete.

(2)Clean. The complete set of equipment for stone milling flour is clean inside and outside; each sliding surface and lead screw, gear, rack, etc. are free from oil and bruises; all parts are free from oil, water, air, and electricity leakage; chips and garbage are cleaned up.

(3)Lubrication. Refuel and change the oil on time, and the oil quality meets the requirements; the oil pot, oil gun, oil cup, linoleum, and oil line are clean and complete, the oil mark is bright, and the oil passage is smooth.

(4)Safety. Implement the system of assigning people and machines and handing over shifts; be familiar with the structure of corn processing machinery and abide by the operating procedures, use equipment reasonably, maintain equipment carefully, and prevent accidents.

Steps to maintain corn milling machine

Steps to maintain corn milling machine

The corn milling machine from Henan Jinrui Food Engineering Co., Ltd. is using dry peeling and degerming technology, which can produce different sizes of corn grits and flour at the same time. And different customers' processing need can be customized here to meet various of needs such as brewery, snack food, glucose, sugarhouse and etc. Also, we have an independent technology research and development team, a professional manufacturing team and after-sales service team, which will escort your product quality and after-sales experience. So if you’re interested in corn milling machine, welcome to contact Henan Jinrui.

PREV:What are the methods to reduce the power consumption of complete set rice mill machine?

PREV:What are the methods to reduce the power consumption of complete set rice mill machine?

NEXT:Is there wheat flour milling machine suitable for small business?

NEXT:Is there wheat flour milling machine suitable for small business?

Leave a message

If you wanna to get more details about equipment quotation or service, phone: 008613526615783, you can send E-mail to sales@doingoilmachine.com. Or you can leave a message in below form. We will contact youASAP.